Rapid Manufacturing on Demand

1 to 1000+ Metal and Plastic Parts

Global delivery as fast as 10 days

CNC Machining Services

Mester provides a variety of CNC machining services including milling, turning, EDM (electrical discharge machining) and wire EDM, and surface grinding. With our precision 3-, 4- and 5-axis CNC machining centers, combined with other advanced capabilities and our experienced team, we can handle all technical aspects of creating your prototypes and parts, so your team can focus on bringing your product to market. Contact us today to get your manufacturing solution and details.

Mester Advantages

There are huge amount of CNC machining service providers. Why choose us?

- Experience: Our engineers have built up rich experiences from the previous projects, so that they can handle complex and precision parts without any problem.

- Facilities: With HAAS 3,4,5 axis CNC, Hexagon CMM, Olympus handheld XRF analyzer, your parts will be manufacture and inspect with advanced equipment in-house.

- Fast Turnaround: Average quote returned in 24 hours, parts ship within 7 days or less, 99% on-time delivery and quality rate.

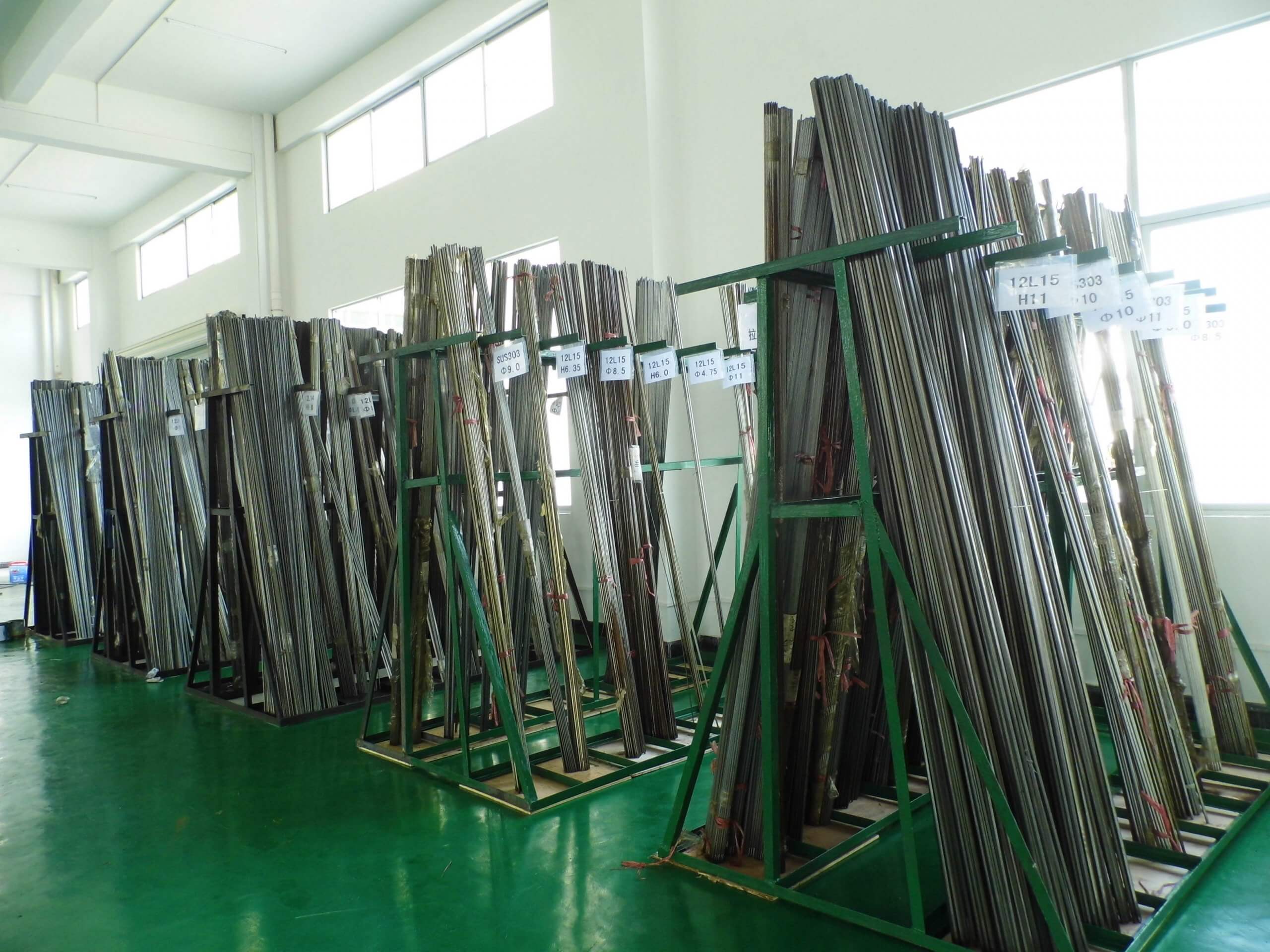

CNC Turned Parts

CNC lathes allows us get high speed turning of both plastics and metals from bar or block material. The turning process allows for complex external and internal geometries including all kind of thread to be generated. For any round shape components, CNC turning is an more efficient way compare with CNC milling. For example, shafts, worms, spheres…Our turning capacity is available prototypes through mass production.

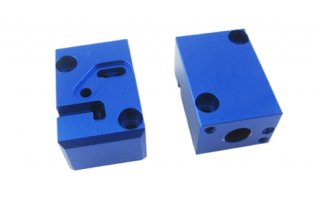

CNC Milled Parts

We offer both 3 and 5-axis machining capabilities. To optimize for speed of production, we recommend minimizing the number of setups to leverage 3-axis machining.

CNC Machining Surface Finishes

| As Machined (standard) | ~125 RA µin (3.2 RA µm). Minor tool marks will be visible on the part. Surface finish requirements can be increased to 63, 32, or 16 RA µin. |

| Bead Blast | Matte finish with light texture is achieved by blowing small glass beads against the part. |

| Anodizing Type II | Corrosion resistant finish. A variety of different colors can be applied when anodizing. |

| Anodizing Type III | Adds a wear resistant layer on top of the corrosion resistance of Type II. |

| Powder Coat | Strong, wear and corrosion resistant finish, that is more durable than the methods mentioned above. Powder coat finishing are available in large range of colors. |

Other surface finishes are available upon request, for more please see our surface finishing services.

CNC Machining Tolerances

With high precision milling & turning machines, we are able to catch super tight tolerance. Parts will be made accordingly to our customers’ specification. If 2D drawings are not available, you can also indicate with ISO 2678. The table below is the ISO 2678 standard for your reference.

| Tolerance Lever | Overall Dimension Range | ||||||

| Specification | «3,›0.5 | «6,›3 | «30,›6 | «120,›30 | «400,›120 | «1000,›400 | «2000,›1000 |

| Tolerance Standard | |||||||

| F | ±0.05 | ±0.05 | ±0.1 | ±0.15 | ±0.2 | ±0.3 | ±0.5 |

| M | ±0.1 | ±0.1 | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 |

| C | ±0.2 | ±0.3 | ±0.5 | ±0.8 | ±1.2 | ±2 | ±3 |

| V | – | ±0.5 | ±1 | ±1.5 | ±2.5 | ±4 | ±6 |

CNC Machining Materials

Plastic: ABS, PC, ABS+PC, PP, PS, POM, PMMA (Acrylic), PAGF30, PCGF30, Teflon, DHPE, HDPE, PPS, PEEK

Metal: Aluminum, Steel, Stainless Steel (17-4, inconel 625 & 718), Magnesium, Titanium, Zinc, Brass, Bronze, Copper

These materials are the most common ones. If you don’t see the material you need listed here, please check with our project managers.

Application and Market

Applications: Jigs & fixtures, Rapid tooling, R & D projects, Post-machining, CNC prototyping, Vibration bowl and End-use parts.

Market: Automotive, Medical Device, Consumer Electronics, Home Appliance, Aerospace, Packaging, for more please see industries.

CNC Machined Metal & Plastic Parts