Rapid Manufacturing on Demand

1 to 1000+ Metal and Plastic Parts

Global delivery as fast as 10 days

Plastic injection molding

Plastic injection molding is, by far, the most popular industrial technique for making large volumes of identical goods. Injection molding is a process for producing parts by injecting material into a mold.

Mester Hardware specializes in custom injection molded and phenolic molded products. We will assist your company in fulfilling the project requirements from color, strength, inserts, pad printing and texture. With direct importing, we can ensure the highest quality at the most competitive price.

Mester Advantages

There are huge amount of CNC machining service providers. Why choose us?

- Experience: Our engineers have built up rich experiences from the previous projects, so that they can handle complex and precision parts without any problem.

- Facilities: With HAAS 3,4,5 axis CNC, Hexagon CMM, Olympus handheld XRF analyzer, your parts will be manufacture and inspect with advanced equipment in-house.

- Fast Turnaround: Average quote returned in 24 hours, parts ship within 7 days or less, 99% on-time delivery and quality rate.

Plastic Injection Molding Applications:

Automotive

Audio/Video

Lawn/Garden

Food/Beverage service

Medical

Furniture

Plastic Injection Molding Materials:

Acetal is strong, fatigue resistant, moisture resistant and chemical resistant

PP (polypropylene) is chemical resistant, elasticity, fatigue resistant and resists electricity

HDPE (high Density Polyethylene) is cost effective, withstands high tems, UV-resistant and resistant to most chemicals

Nylon does not burn, resistant to corrosion, high amount of insulation and offers high wear resistance.

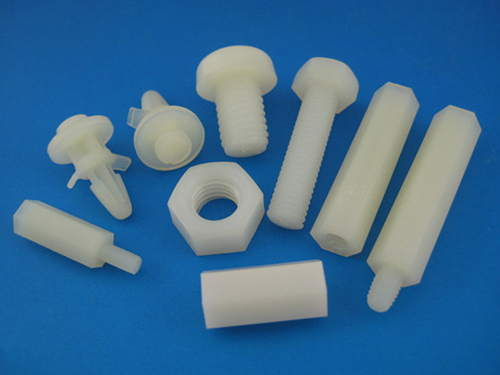

Products produced by injection molding process vary in size, complexity and application and offer many benefits.

Benefits Of Injection Molding:

| 1. | Form complex shapes |

| 2. | Excellent surface finish |

| 3. | Dimensional accuracy |

| 4. | High production rate |

| 5. | Scrap can be recycled |

Other surface finishes are available upon request, for more please see our surface finishing services.

Plastic Injection Molding Materials:

Acetal is strong, fatigue resistant, moisture resistant and chemical resistant

PP (polypropylene) is chemical resistant, elasticity, fatigue resistant and resists electricity

HDPE (high Density Polyethylene) is cost effective, withstands high tems, UV-resistant and resistant to most chemicals

Nylon does not burn, resistant to corrosion, high amount of insulation and offers high wear resistance.

Products produced by injection molding process vary in size, complexity and application and offer many benefits. These materials are the most common ones. If you don’t see the material you need listed here, please check with our project managers.

Benefits Of Injection Molding:

Excellent surface finish

Dimensional accuracy

High production rate

Low labor cost

Scrap can be recycled

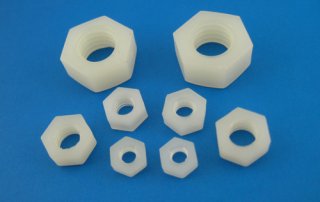

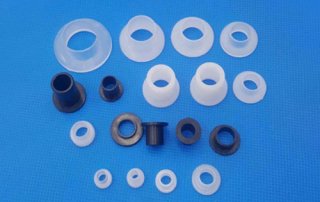

Plastic Injection Molding Parts: